How Building Product Manufacturers Can Win More Business Despite COVID-19

2020 has been an interesting year for building product manufacturers. With COVID-19 testing the resiliency of the building industry and material costs the highest we’ve seen in years, savvy building product manufacturers are leveraging future-looking construction data with well-managed takeoff practices to grow while others are flailing. Read on to learn how to find more […]

5 Ways to Grow Your Construction Company

[av_slideshow size=’featured’ animation=’slide’ autoplay=’false’ interval=’5′ control_layout=’av-control-default’] [av_slide slide_type=’image’ id=’1172′ video=” mobile_image=” video_ratio=” title=” link_apply=” link=’lightbox’ link_target=”][/av_slide] [/av_slideshow] [av_heading heading=’5 Ways to Grow Your Construction Company’ tag=’h2′ style=’blockquote modern-quote modern-centered’ size=” subheading_active=” subheading_size=’15’ padding=’10’ color=’custom-color-heading’ custom_font=’#000000′ admin_preview_bg=”][/av_heading] [av_textblock size=” font_color=” color=’#000000′ admin_preview_bg=”] Most constructions professionals would agree, growing a construction company can be a very difficult […]

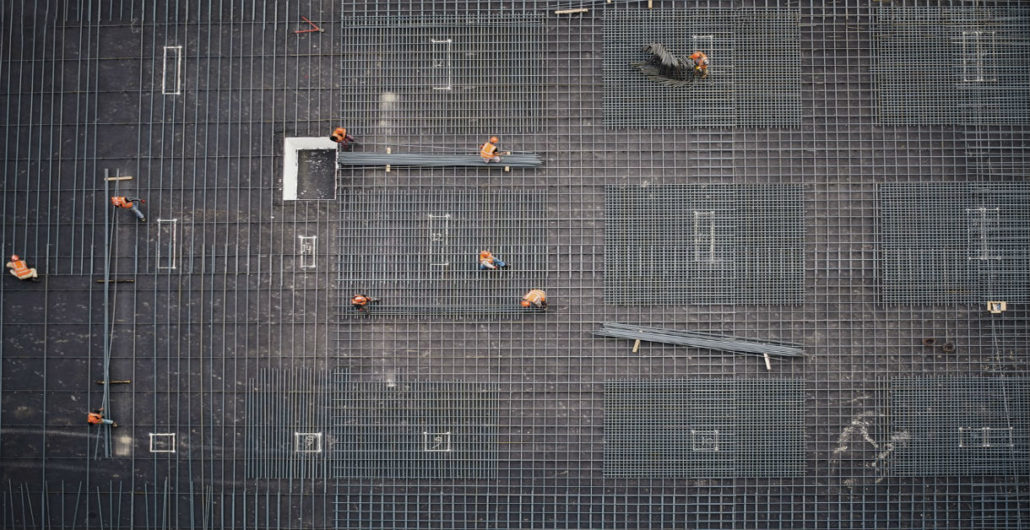

3 Benefits of Outsourcing Quantity Takeoffs

[av_slideshow size=’featured’ animation=’slide’ autoplay=’false’ interval=’5′ control_layout=’av-control-default’] [av_slide slide_type=’image’ id=’1323′ video=” mobile_image=” video_ratio=” title=” link_apply=” link=’lightbox’ link_target=”][/av_slide] [/av_slideshow] [av_heading tag=’h2′ padding=’10’ heading=’3 Benefits of Outsourcing Quantity Takeoffs’ color=’custom-color-heading’ style=’blockquote modern-quote modern-centered’ custom_font=’#000000′ size=” subheading_active=” subheading_size=’15’ custom_class=” admin_preview_bg=”][/av_heading] [av_textblock size=” font_color=” color=’#000000′ admin_preview_bg=”] A number of Construction Professionals – from Contractors to Building Material Suppliers – are […]

Getting Your Project Estimate Right The First Time

In the world of construction estimation, accuracy is king. Experienced estimators are all too familiar with what can happen when an estimate ends up totally misplaced with its original intentions. Anything can happen before, during, and after the estimate to throw a wrench into the works; as a project manager or estimator, it’s up to […]

What Is A Quantity Takeoff?

The construction industry is a highly competitive business where the easiest mistakes to make can end up costing thousands of dollars for your organization. Accuracy is a necessity, and a company that can’t reliably offer it 100% of the time is at a disadvantage to everyone else when it comes to handling bids, contracts, and […]